Custom thermoforming is a plastic manufacturing process that allows you to create larger plastic parts with a much lower tooling cost than other plastic processes.

Thermoformed products can be formed from the same plastics, so there is no need to compromise on physical properties. Thermoformed sheets can be made with high-impact and flame-retardant properties in an infinite range of colors.

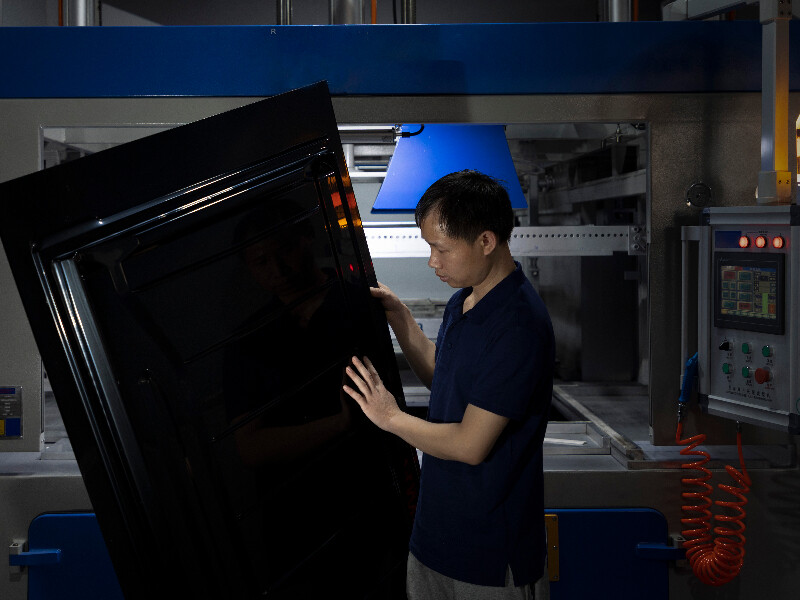

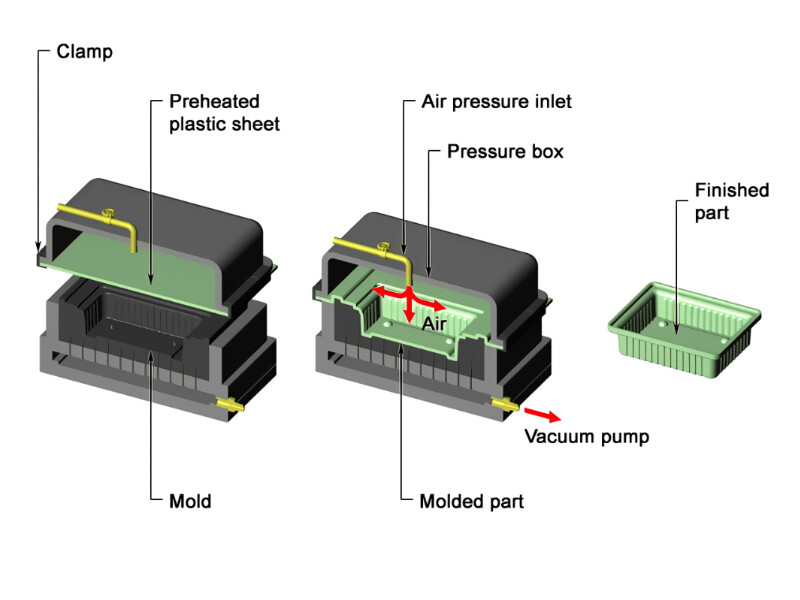

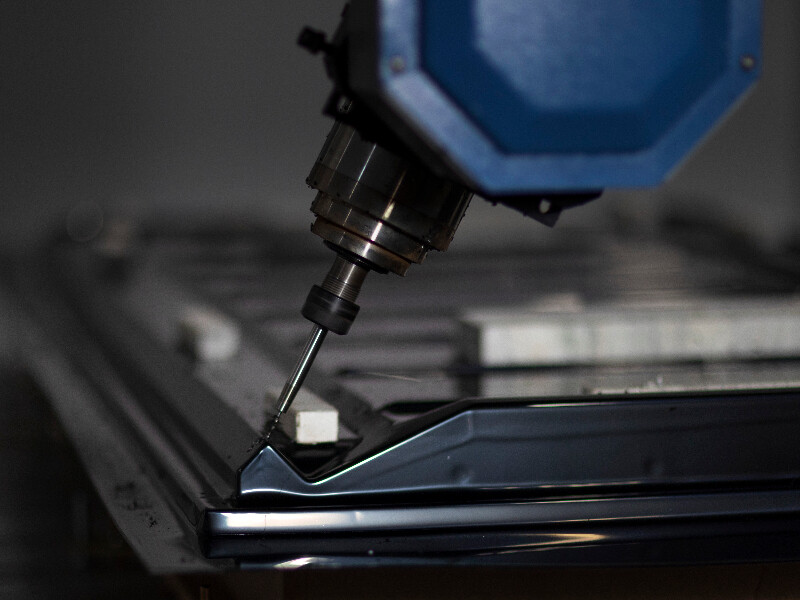

Vacuum forming is a process where plastic sheets are heated, shaped over a mold using vacuum pressure, and cooled to hold their form. Using advanced 3D trimming equipment, we finish the parts with precision and consistency

Pressure forming is an advanced process where plastic sheets are shaped using vacuum and pressure for more detailed designs. It builds on vacuum forming, adding pressure to create parts with sharper, more precise details.

Vacuum forming is a simple way to shape plastic. It works by heating the plastic, then using suction to pull it over a mold. It’s extremely versatile and works great for everything from packaging to custom parts.

With our in-house engineering expertise and global partnerships, we deliver tailored solutions to manufacturers worldwide.

With a proven track record in collaborating with OEM manufacturers and tier 1 and 2 automotive suppliers, we seamlessly operate within global supply chains.

Copyright 2025 Versa 3 Technology, Ltd. | Privacy Policy | Cookie Preferences