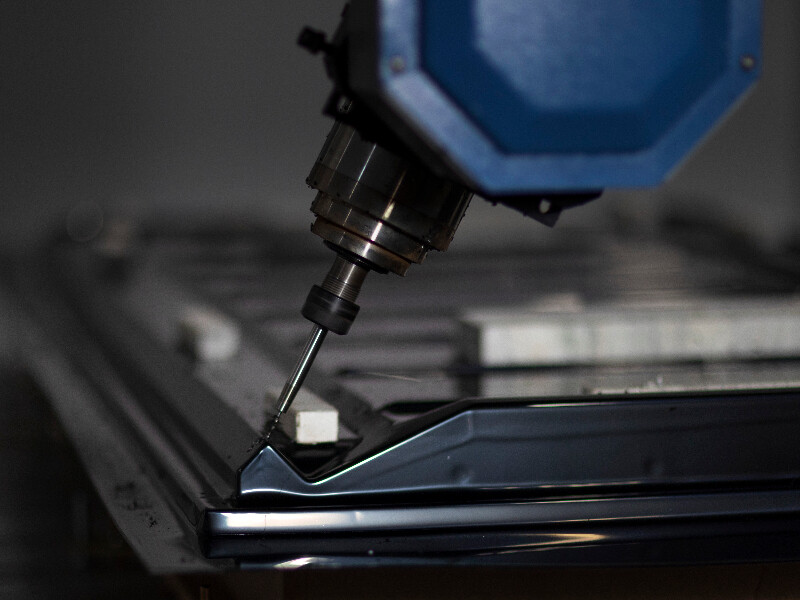

Versa 3 delivers precision technical molding solutions. Our advanced processes ensure high-performance components that integrate seamlessly into your systems, from battery management to complex enclosures.

With expertise in material selection and tool design, we collaborate closely with you to solve unique challenges and deliver components that meet exact specifications. When the details matter, Versa 3 provides solutions you can trust.

Two-shot molding provides exceptional flexibility, enabling the creation of complex geometries and multi-colored components for more visually appealing components. By producing the entire part in a single machine with no need for post-processing, this method significantly reduces manufacturing time and helps keep costs down.

Insert molding enhances product structure by embedding metal, plastic, or ceramic components into plastic. It offers a highly efficient alternative to assembling discrete parts with soldering, connectors, fasteners, or adhesives. This process expands plastic capabilities and reduces final product costs by minimizing the use of expensive metals.

Insert molding can also be combined with over-molding, accommodating materials like aluminum, brass, stainless steel, copper, and plastic. This approach delivers improved aesthetics and tailored solutions to better meet design intent.

With our in-house engineering expertise and global partnerships, we deliver tailored solutions to manufacturers worldwide.

With a proven track record in collaborating with OEM manufacturers and tier 1 and 2 automotive suppliers, we seamlessly operate within global supply chains.

Copyright 2025 Versa 3 Technology, Ltd. | Privacy Policy | Cookie Preferences