Bringing a new product to market requires agility in R&D, especially when complex graphic overlays or printed components are involved. At Versa 3, our rapid prototyping capabilities – including 3D printing, CNC machining, and vacuum casting – allow us to quickly turn intricate designs into precise, functional prototypes, helping you test, refine, and validate every detail with speed and flexibility.

Let Versa 3 help bring your ideas to life with tailored prototyping solutions that drive innovation and accelerate product development. Contact us today to get started!

3D printing builds parts layer by layer directly from digital designs, offering unmatched flexibility and rapid iteration.

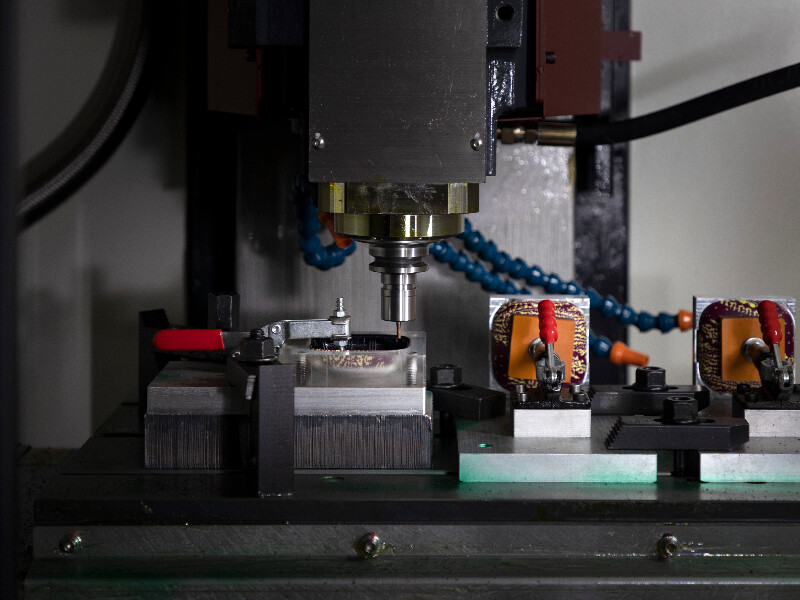

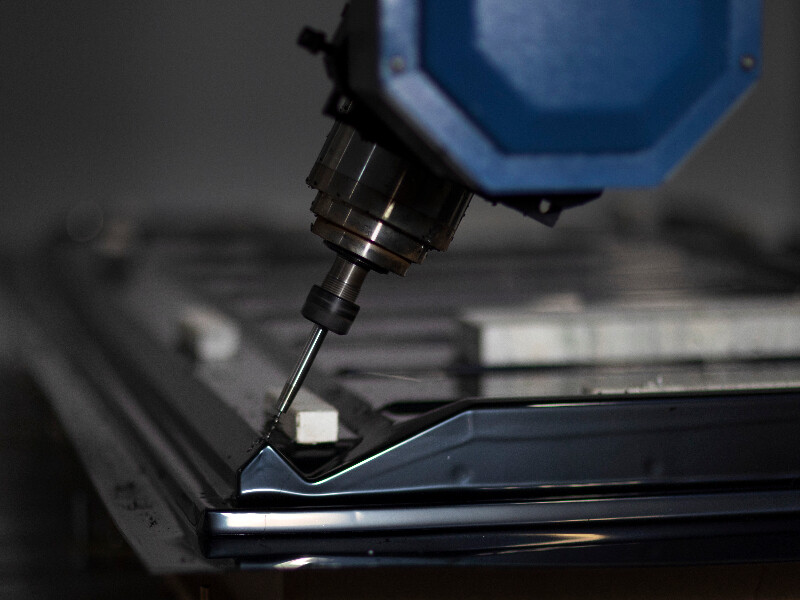

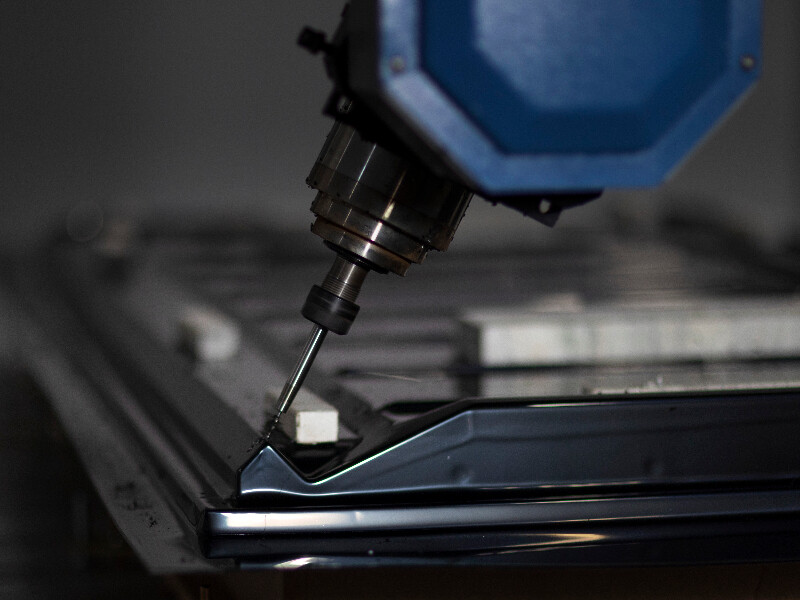

CNC machining delivers highly accurate prototypes by cutting material from solid blocks with computer-controlled tools.

Vacuum casting uses silicone molds to produce detailed, high-quality parts ideal for bridging the gap between prototyping and production.

With our in-house engineering expertise and global partnerships, we deliver tailored solutions to manufacturers worldwide.

With a proven track record in collaborating with OEM manufacturers and tier 1 and 2 automotive suppliers, we seamlessly operate within global supply chains.

Copyright 2025 Versa 3 Technology, Ltd. | Privacy Policy | Cookie Preferences